The Art of Manufacturing by Sugita Wire

Shaping the future through trusted quality and agile manufacturing.

-

Combining technologies of cold heading wire and spring wire

We are one of the few manufacturers in Japan that specialize in both cold heading wire and spring wire. By integrating the technologies and equipment developed in each field, we offer a hybrid manufacturing approach that meets a wide range of applications and demanding quality standards.

-

Flexible production capabilities to handle small lots, high-mix orders, and short lead times.

To meet the diverse needs of our customers, we support a wide range of wire diameters from 0.4 mm to 55.0 mm. With over 6,000 combinations of steel grades and wire sizes, we are highly flexible in accommodating specification changes and prototyping requests.

We also maintain strict inventory control of materials and finished products, enabling quick delivery for high-mix, low-volume production.

-

Environmentally Friendly Product Line

Cold heading wire and oil-tempered wire can be processed at room temperature without the need for heating or heat treatment.

Utilizing our diverse production facilities, we have developed non-quenched and tempered steel wire that does not require post-forming heat treatment.

Our product lineup also includes a water purification material made from recycled waste sulfuric acid, contributing to environmental sustainability.

-

Trusted quality, proven manufacturing. Supporting the future of the automotive industry

Many of our products are used in critical safety components for the automotive and industrial machinery sectors. To meet the industry's strict quality standards, we have established a rigorous quality management system across every stage of the manufacturing process.

From material receiving to final inspection—and even container loading for export shipments—we manage the entire workflow in-house. This integrated approach ensures consistent product quality and total traceability, earning the trust of our customers worldwide.

Manufacturing Process

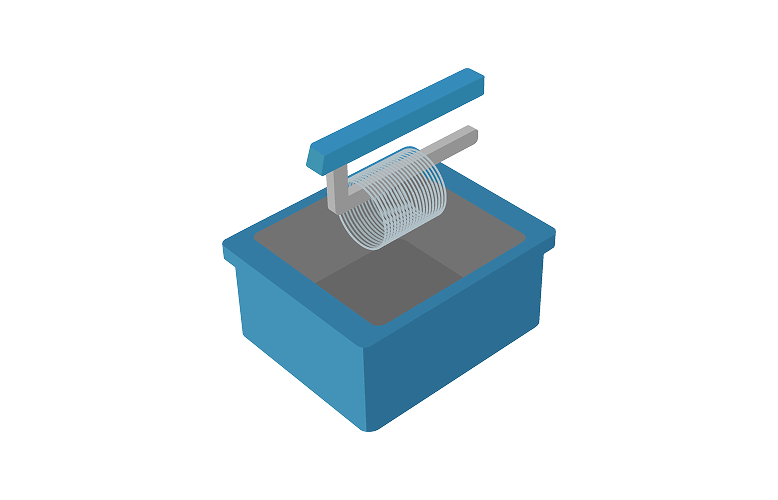

Pickling

We perform acid pickling to dissolve and remove oxide scale formed during hot rolling by steel manufacturers or during our own heat treatment processes.

After cleaning the surface, we apply a suitable coating to ensure lubricity.

This helps reduce friction during wire drawing and cold heading at the customer’s site, improving process efficiency.

Annealing

We create microstructures that can withstand cold forming at the customer's site.

Our heat treatment processes include annealing, patenting, and oil tempering, chosen according to application.

Annealing is mainly used for cold heading wire, transforming the steel into a spheroidized structure for improved formability.

Patenting is a heat treatment where high-carbon or spring steel wire is heated to a high temperature and then cooled to a specified temperature to induce an isothermal transformation, resulting in a fine, tough microstructure.

Oil tempering involves quenching and tempering spring wire to achieve high strength and toughness.

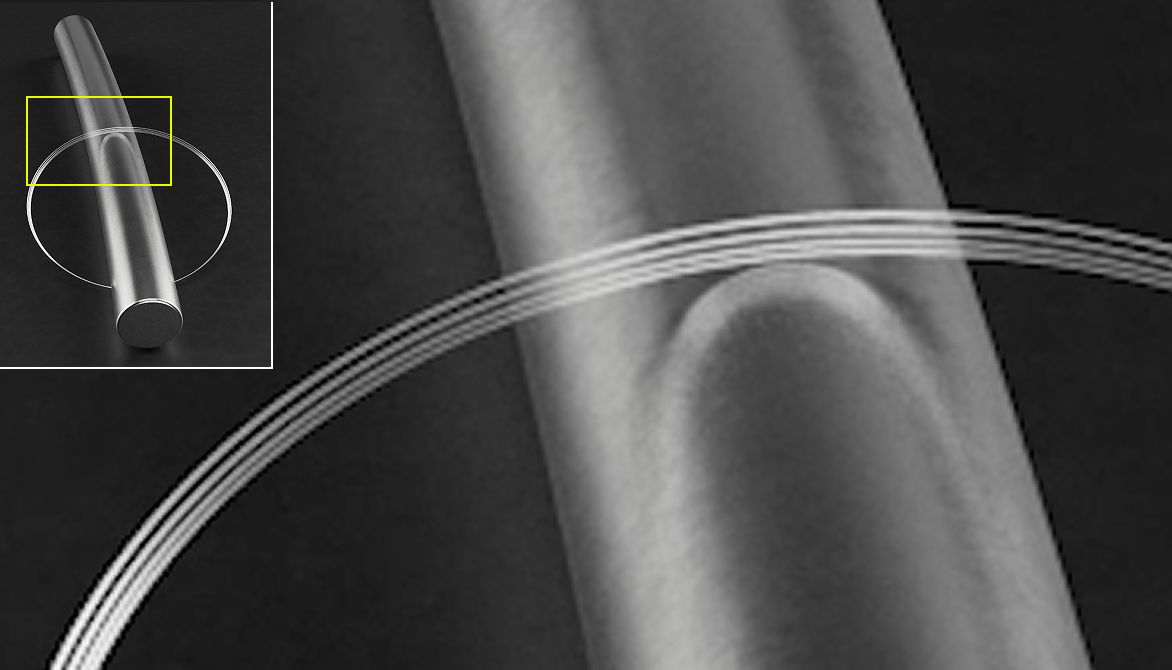

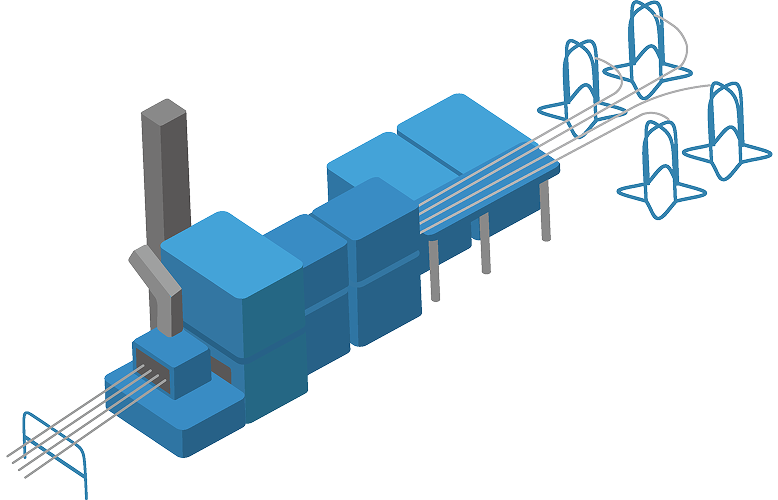

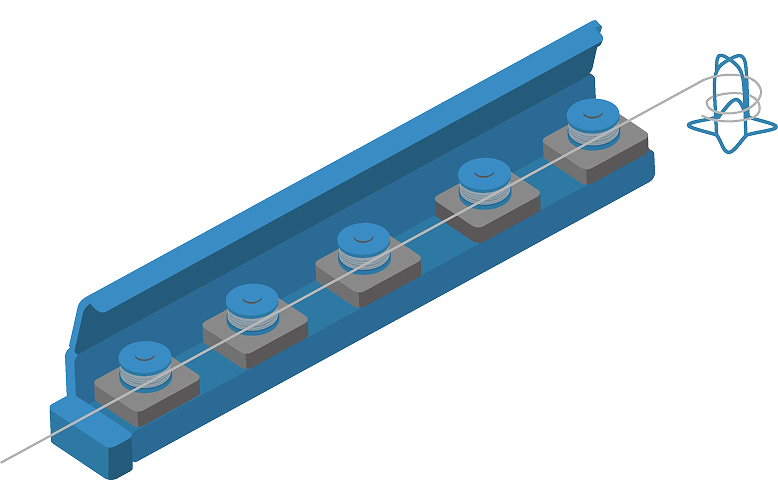

Wire Drawing

We use dies to draw wire to the required diameter.

This process improves strength, formability, roundness, and surface smoothness.

We have various machines including single-die and continuous drawing machines, allowing us to handle a wide range of product types.

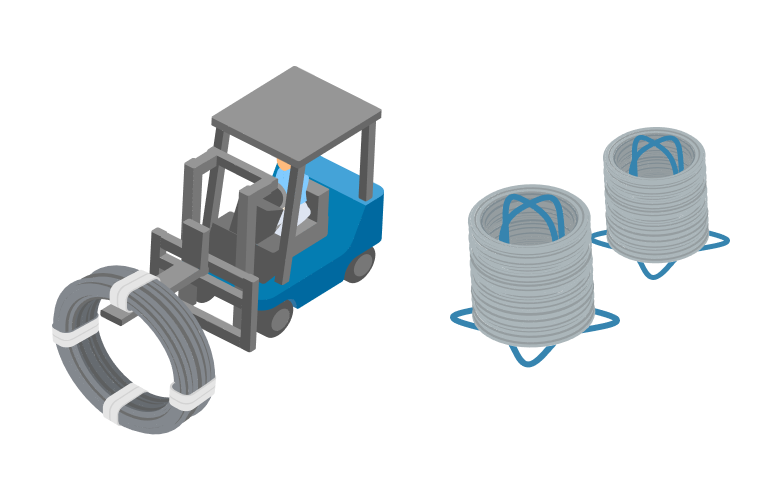

Inspection and shipment

We are equipped with a wide range of inspection systems to accommodate various product types. Based on the specifications agreed upon with our customers, we determine whether each product is ready for shipment. Product that pass inspection are packed and shipped according to customer requirements. For export products, we perform all container loading (vanning) operation in-house to ensure safe and reliable delivery.

Our Commitment to Quality Control

-

Quality Management Based on International Standards

IWe have established and operate a quality management system in compliance with international standards, including ISO 9001 and IATF 16949.

This enables us to effectively meet the strict quality requirements of the automotive industry and other demanding sectors. -

Ensuring Traceability

We assign barcodes to materials upon receipt to prevent mix-ups throughout the production process.

Our traceability system tracks everything from raw material lots to finished products, enabling quick and accurate responses to any issues. -

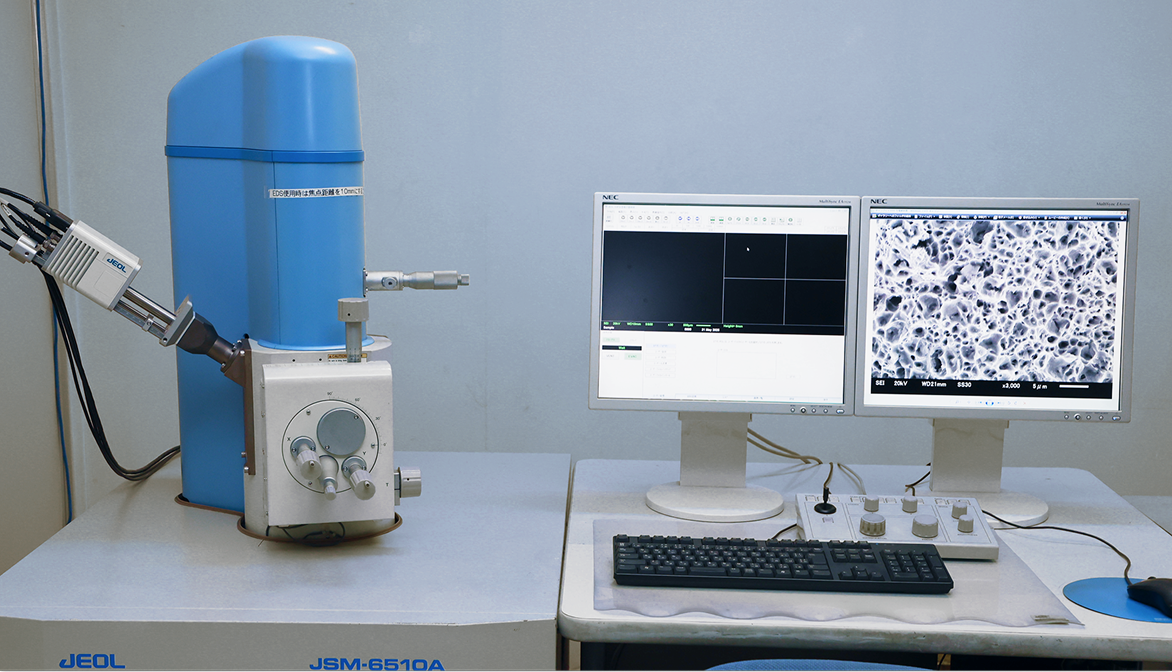

Thorough Prevention of Defects and Outflow

We protect contact points with cushioning materials and conduct thorough visual inspections by operators at each stage to prevent defects and their occurrence.

Some lines are also equipped with ultrasonic flaw detectors to handle applications requiring high sensitivity.